How do we get More for Less?

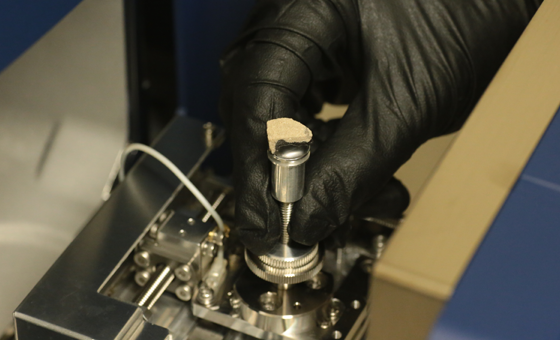

- Third Party (Independent) testing of drilling & completion systems under “real” reservoir-drilling-completion conditions

- We are a “Solutions Driven” company & work for the operator; not the drilling fluid or completion systems company.

- We redesign, optimize and propose alternatives

- We don’t rely on computer modelling, we measure, produce & analyse “real” data at D&C conditions.

- We use our knowledge, experience and “real” data to provide solutions and make recommendations.

- If we don’t have the equipment to solve a unique problem, we design & fabricate to provide a solution.